-

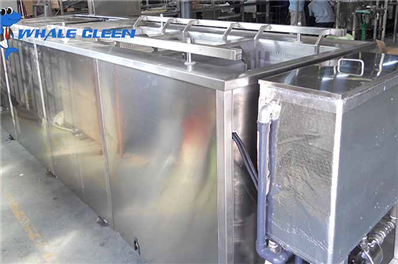

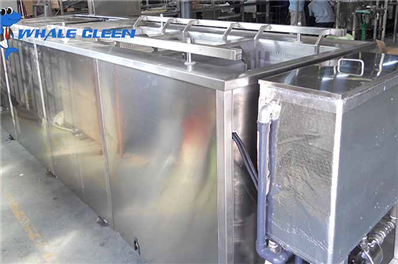

Ultrasonic Cleaning for Metal Storage Tanks: Ensuring Hygiene and Quality

Ultrasonic Cleaning for Metal Storage Tanks: Ensuring Hygiene and Quality

Cleaning metal storage tanks is a crucial process to ensure the hygiene and storage quality of the tanks. Over time, metal tanks can accumulate deposits, residues, and various contaminants on their inner walls, which can impact the integrity of the stored

-

Why Does the Ultrasonic Cleaner Turn Things Black? Unveiling the Causes and Solutions

Why Does the Ultrasonic Cleaner Turn Things Black? Unveiling the Causes and Solutions

Discovering black particles floating in the water or a dark film on your items after ultrasonic cleaning can be alarming. Is your jewelry ruined? Is the machine faulty? In most cases, this "blackening" is a normal—even positive—indicator of the

-

Why Can't Ultrasonic Cleaners Use Thin Steel Sheets? - An Engineering Analysis of Resonance Principles and Material Selection

Why Can't Ultrasonic Cleaners Use Thin Steel Sheets? - An Engineering Analysis of Resonance Principles and Material Selection

In the field of industrial manufacturing and equipment material selection, a fundamental principle is: "The right material for the right application." For ultrasonic cleaners, the choice of material for their core working component—the tank that

-

Why Do Ultrasonic Cleaners Have Multiple Cleaning Stages? The Science Behind the Process

Why Do Ultrasonic Cleaners Have Multiple Cleaning Stages? The Science Behind the Process

Ultrasonic cleaners are widely used in industries such as manufacturing, healthcare, jewelry, and automotive for their ability to clean intricate items with precision. However, many users wonder why these machines often involve multiple cleaning stages in

-

Why Did It Rust After Ultrasonic Cleaning? The Causes and Prevention Guide

Why Did It Rust After Ultrasonic Cleaning? The Causes and Prevention Guide

You carefully place your metal items into the ultrasonic cleaner, expecting them to come out sparkling clean. Instead, you find unsightly orange or brown spots—rust. It's a frustrating and confusing experience.Why did it rust after ultrasonic cleaning

-

Is Ultrasonic Cleaner Power High? Why? Understanding Power Ratings and Their Impact on Cleaning Performance

Is Ultrasonic Cleaner Power High? Why? Understanding Power Ratings and Their Impact on Cleaning Performance

Ultrasonic cleaners are widely used in industries ranging from manufacturing to healthcare, but many users wonder about their power consumption and why high power is often emphasized. Understanding the relationship between power and cleaning efficiency is

-

Why Do Ultrasonic Cleaners Have Temperature Control? The Science Behind the Heat

Why Do Ultrasonic Cleaners Have Temperature Control? The Science Behind the Heat

If you've shopped for or used an ultrasonic cleaner, you've likely noticed that many models come with a built-in heating function and a temperature control setting. This might lead you to wonder: if the cleaning power comes from ultrasonic waves,

-

What Adhesive is Used for Ultrasonic Cleaner Transducers? The Complete Bonding Guide

What Adhesive is Used for Ultrasonic Cleaner Transducers? The Complete Bonding Guide

Ultrasonic cleaner transducers (also called piezoelectric vibrators or "振子" in Chinese) require specialized adhesives to ensure optimal performance an……

-

Ultrasonic Cleaner Intensity Testing: 5 Proven Methods for Accurate Measurement

Ultrasonic Cleaner Intensity Testing: 5 Proven Methods for Accurate Measurement

1. Why Test Ultrasonic Cleaner Intensity? Impact on cleaning efficiency: Low intensity = poor contaminant removal; excessive intensity = part damage Industry standards: ISO 17223:2014 for ultrasonic power measurement

-

How to Use Ultrasonic Cleaners for Automotive Repair? A Step-by-Step Guide

How to Use Ultrasonic Cleaners for Automotive Repair? A Step-by-Step Guide

1. Why Use Ultrasonic Cleaners in Automotive Repair? Ultrasonic cleaning is a game-changer for auto shops and DIY mechanics because: Deep Cleaning: Removes 90%+ of contaminants (oil, carbon, rust) from complex parts like fuel injectors.

-

The Complete Guide to Cleaning PCBs with Ultrasonic Cleaners: 5-Step Process for Optimal Results

The Complete Guide to Cleaning PCBs with Ultrasonic Cleaners: 5-Step Process for Optimal Results

1. The Importance of Proper PCB Cleaning: Industry Insights According to the 2024 Global Electronics Manufacturing Report: Improper cleaning causes 35% of PCB failures Ultrasonic cleaning improves solder joint reliability

-

How to Adjust Temperature on Ultrasonic Cleaners: A Complete Guide

How to Adjust Temperature on Ultrasonic Cleaners: A Complete Guide

Studies show that proper temperature control can improve cleaning efficiency by up to 40% and extend equipment life by 2-3 years. This guide will walk you through the steps to master temperature adjustment on your ultrasonic cleaner. 1. Understanding T

Ultrasonic Cleaning for Metal Storage Tanks: Ensuring Hygiene and Quality

Ultrasonic Cleaning for Metal Storage Tanks: Ensuring Hygiene and Quality

Why Does the Ultrasonic Cleaner Turn Things Black? Unveiling the Causes and Solutions

Why Does the Ultrasonic Cleaner Turn Things Black? Unveiling the Causes and Solutions

Why Can't Ultrasonic Cleaners Use Thin Steel Sheets? - An Engineering Analysis of Resonance Principles and Material Selection

Why Can't Ultrasonic Cleaners Use Thin Steel Sheets? - An Engineering Analysis of Resonance Principles and Material Selection

Why Do Ultrasonic Cleaners Have Multiple Cleaning Stages? The Science Behind the Process

Why Do Ultrasonic Cleaners Have Multiple Cleaning Stages? The Science Behind the Process

Why Did It Rust After Ultrasonic Cleaning? The Causes and Prevention Guide

Why Did It Rust After Ultrasonic Cleaning? The Causes and Prevention Guide

Is Ultrasonic Cleaner Power High? Why? Understanding Power Ratings and Their Impact on Cleaning Performance

Is Ultrasonic Cleaner Power High? Why? Understanding Power Ratings and Their Impact on Cleaning Performance

Why Do Ultrasonic Cleaners Have Temperature Control? The Science Behind the Heat

Why Do Ultrasonic Cleaners Have Temperature Control? The Science Behind the Heat

What Adhesive is Used for Ultrasonic Cleaner Transducers? The Complete Bonding Guide

What Adhesive is Used for Ultrasonic Cleaner Transducers? The Complete Bonding Guide

Ultrasonic Cleaner Intensity Testing: 5 Proven Methods for Accurate Measurement

Ultrasonic Cleaner Intensity Testing: 5 Proven Methods for Accurate Measurement

How to Use Ultrasonic Cleaners for Automotive Repair? A Step-by-Step Guide

How to Use Ultrasonic Cleaners for Automotive Repair? A Step-by-Step Guide

The Complete Guide to Cleaning PCBs with Ultrasonic Cleaners: 5-Step Process for Optimal Results

The Complete Guide to Cleaning PCBs with Ultrasonic Cleaners: 5-Step Process for Optimal Results

How to Adjust Temperature on Ultrasonic Cleaners: A Complete Guide

How to Adjust Temperature on Ultrasonic Cleaners: A Complete Guide